Previously, we have posted light controlled digital fan regulator, with which we can control the speed of the fan remotely from the bed with the help of a torchlight. Now, here is another light-operated project which can also operate remotely from the bed with a torchlight. The group electronics hobbyist at Best Engineering Projects designed and verified a very unique electronic circuit light operated internal door latch with which one can close or open the door of your room remotely.”

Check out other security-related projects posted on bestengineeringproject.com

- Car Lock System using Arduino and GSM

- Arduino Fingerprint Sensor Lock

- Arduino and RFID based Door Access System

- Electronic Code Lock Circuit

- RFID Based Security System Using Microcontroller AT89C52

Circuit Description of Light Operated Internal Door Latch

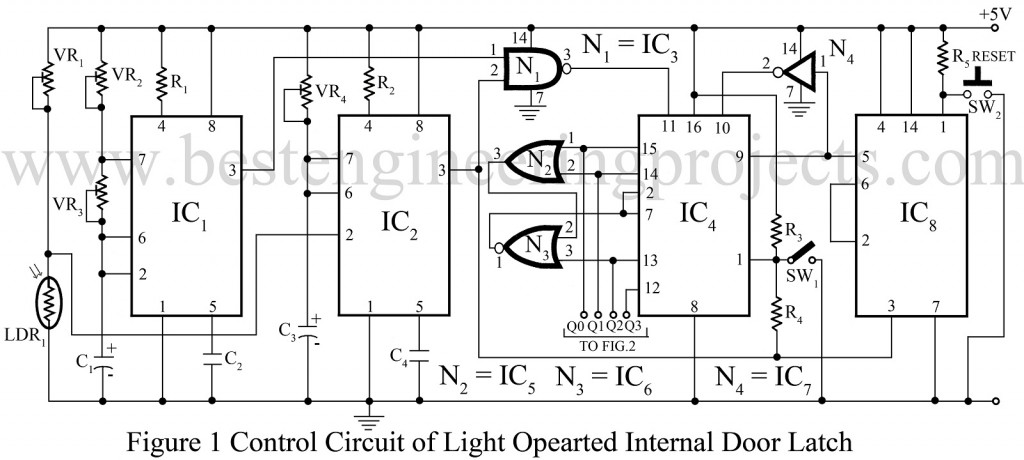

The circuit of the light-operated internal door latch is built using a control unit and drive unit for the stepper motor. The light-dependent resistor is used here as a sensor, whose value is varied according to the intensity of light falling on it.

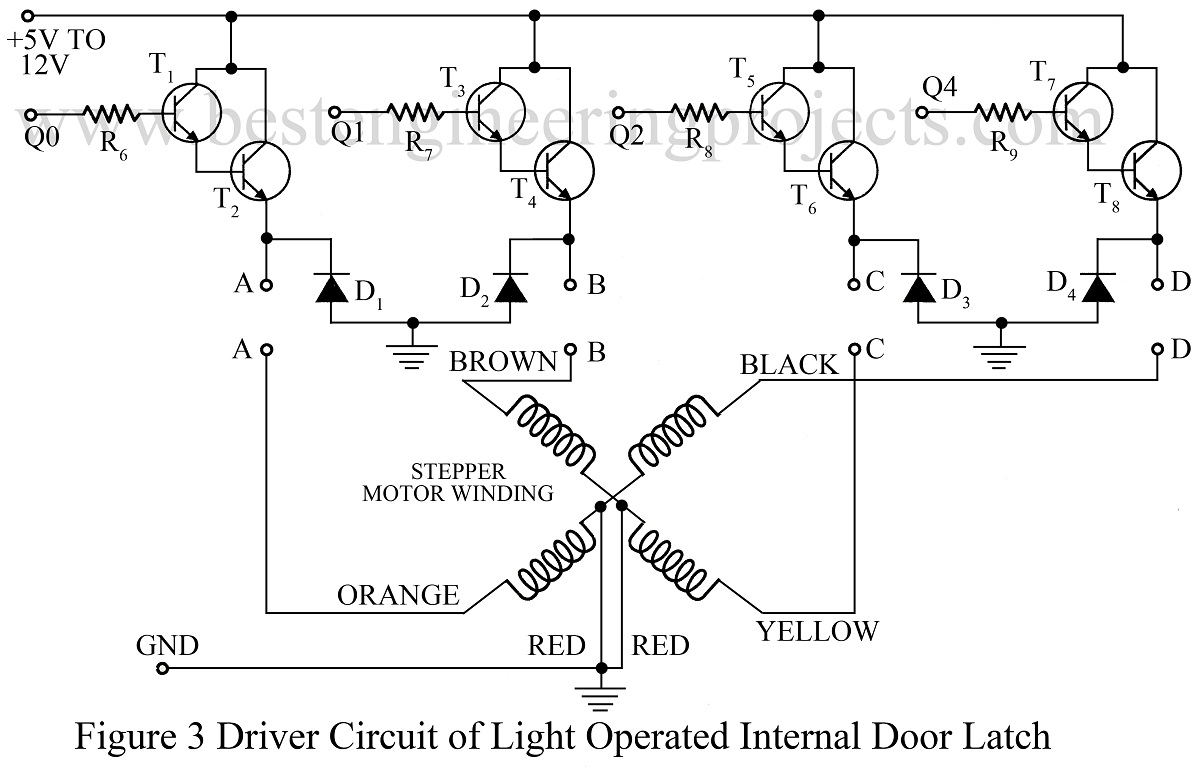

The control unit for the stepper motor is built around two timer ICs (IC1 and IC2), NAND gat IC (IC3), 4-bit bi-directional universal shift resistor (IC4), OR gate IC (IC5), NOR gate IC(IC6) hex inverter IC(IC7) and dual D-type positive-edge triggered flip-flop IC (IC8) where driver unit utilizes four Darlington pair transistor (T1 and T2, T3 and T4, T5 and T6, T7and T8) to increase the correct capability for operating the stepper motor.

IC1 is here configured as an astable multivibrator for 1.5 seconds. IC2 is configured as a monostable multivibrator and gets triggered from LDR1 when the torchlight is focused on LDR1. The sensitivity of LDR1 is adjusted by potentiometer VR1 to avoid the activation by ambient light LDR1 is covered.

IC2 is configured as a monostable multivibrator and is triggered when a torchlight is focused on LDR1. The period of 15 seconds is adjusted by potentiometer VR4. Both the output (output from IC1 and IC2) is fed to NAND gate IC (IC3). The output of NAND gate IC (IC3) is given to the clock pin of IC4. The Q0 and Q1 outputs of shift register IC4 are ORed by using OR gate IC (IC5) and its output is fed to NOR GATE IC (IC6) The Q2 output forms the second input for NOR gate IC (IC6).

The output of NOR is given to pins 2 and 7 (shift-right and shift-left serial data input pin) of IC4. Mode control inputs S0 and S1 are used for direct charging of shift register IC4. The Q1 output of dual D-type flip-flop IC8 is fed to S0 directly and S1 after inversion by N4 (IC7). The output of IC2 from pin3 is connected to reset pin1 of IC4 through resistor R 4 to reset IC4 to step the stepper motor. You can also stop the stepper motor manually by pushing switch SW1 to the ‘on’ position.

The output of IC2 is also given to clock pin 3 of IC8. IC8 is used herein trigger mode by connecting pins 2 and 6 directly. Switch SW2 is used to reset IC8. The driver circuit and winding circuit of the stepper motor are shown in figure 2. Connect Q0 through Q3 outputs of IC4 in fig 1 to positive and ground power supply terminals of figure 2. The wave from the drive pattern of shift outputs of IC4 is shown in table 1.

|

Table 1 |

||||

|

Shift Register Output Waveform |

||||

|

Clock |

Q3 |

Q2 |

Q1 |

Q0 |

|

1 |

0 |

0 |

0 |

1 |

|

2 |

0 |

0 |

1 |

0 |

|

3 |

0 |

1 |

0 |

0 |

|

4 |

1 |

0 |

0 |

0 |

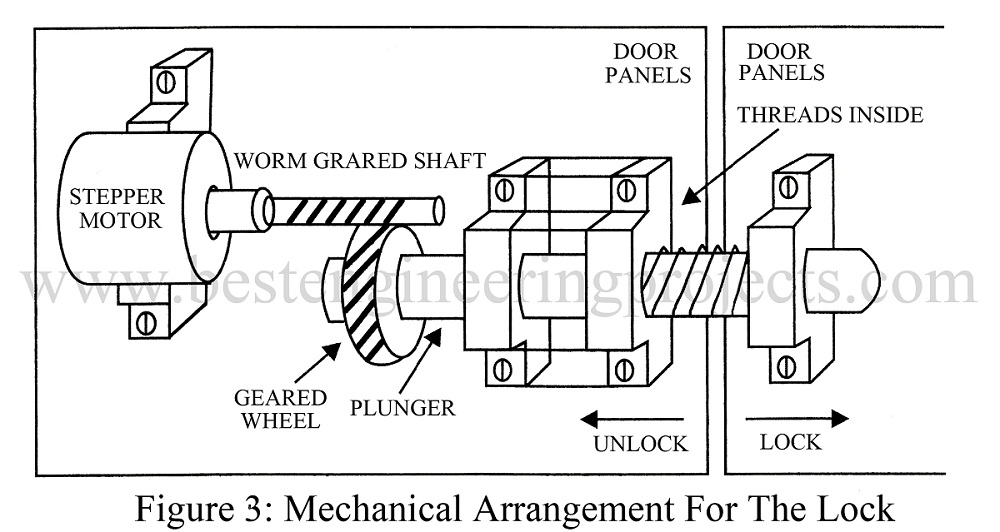

Figure 3 shows the locking arrangement operated by the stepper motor.

When you direct the torchlight on the LDR, the stepper motor runs in one direction to latch the door. If you again focus the torchlight on the LDR, the stepper motor runs in the reverse direction to open the latch.

BEP NOTE: During testing at BEP LAB, a stepper motor for reading/write head positioning in a 1.2 Mb Floppy disk drive unit, operating at 12V with 3.6-degree revolution per step, was used. Connect the colored terminal wires of the motor to the driver unit as shown in figure 2.

PARTS LIST OF LIGHT OPERATED INTERNAL DOOR LATCH

|

Resistor (all ¼-watt, ± 5% Carbon) |

|

R1 – R3, R5 – R9 = 1 KΩ R4 = 100 KΩ VR1 – VR3 = 47 KΩ VR4 = 200 KΩ |

|

Capacitors |

|

C1 = 1 µF, 16V (Electrolytic Capacitor) C2, C4 = 0.01 µF (Ceramic Disc) C3 = 200 µF, 16V (Electrolytic Capacitor) |

|

Semiconductors |

|

IC1, IC2 = NE555 (Timer IC) IC3 (N1) = 7400 (Quad Two input NAND Gate) IC4 = 74LS194 (4-bit bidirectional universal shift register) IC5(N2) = 7432 (Quad Two input OR Gate) IC6 (N3) = 7402 (Quad two input positive NOR Gate) IC7 (N4) = 7404 (HEX Inverter) IC8 = 7474 (Dual Positive Edge Trigger D Flip-Flop) T1, T3, T5, T7 = BC547 (General Purpose silicon NPN Transistor) T2, T4, T6, T8 = BD139 (medium power NPN Silicon Transistor) D1 – D4 = 1N4007 (Rectifier Diode) |

|

Miscellaneous |

|

SW1 = ON/OFF Switch SW2 = Push-to-on switch Stepper Motor LDR |

Thank you sir for posting this type of innovative project. I am planing to build this projects. It this circuit working?

Yes Mr. Prince Gupta this circuit is tested and verified in BEP lab and is 100% working

Thank you sir very much for this innovative idea, i want to design a power supply unit with digital control facility. Would you please post about this projects

We have posted the exact digital control power supply you may check http://bestengineeringprojects.com/electronics-projects/universal-digital-power-supply-circuit/