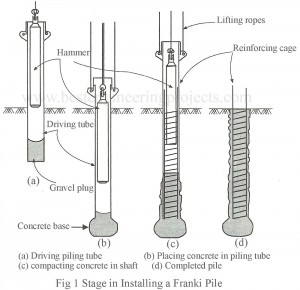

Table 1 Advantages and Disadvantages of the Piles According to the Different Installation Methods No. Advantage or Disadvantage Driven Piles Driven & Cast in place piles Bored Piles 1 Pile integrity can be cheeked prior to installation Yes(adv) No No 2 Pile can be driven to a pre-determined set (assuring that the bearing layer has been reached) Yes(adv) Yes No 3 Ease of construction when water table is present Yes(adv) No No 4 During installation the fresh concrete can be damaged due to ground water No(dis.) Yes Yes 5 Possible…

Read MoreConstruction of Pile Foundation

Driven and Cast-in-Piles Procedure Bored and Cast-in-Situ Piles Procedure

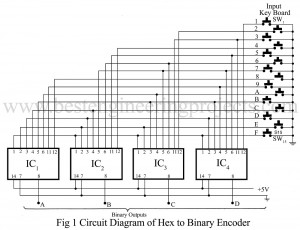

Read MoreHex to Binary Converter Circuit

The circuit described here is a hex to binary converter circuit using four, 8-input NAND gate 7430 ICs. The input keyboard switches SW1 to SW15 are connected in such a manner that the pressing of any switch produces the binary ABCD outputs of the corresponding decoded numbers. When all inputs in a NAND gate are high, it produces a low output, But when any of its input goes low, its output becomes high. Normally, all switches are open, the binary output is 0000. Pressing a switch gives a ‘low input’…

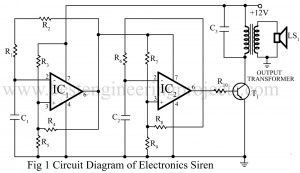

Read MoreElectronic Siren Circuit using OP-Amp 741

Here is an inexpensive electronic siren circuit built around the most popular and low-cost IC 741. The circuit is basically a square wave generator that is used here to produce the tone of a siren. Circuit Description of Electronic Siren Circuit using OP-Amp 741 The IC1 is used as a low-frequency multivibrator, the output of which modulates the high-frequency tone produced by the IC2 multivibrator. The final output is amplified and converted into a loud siren by transistor T1 and the speaker. Various interesting tones can be obtained by changing the…

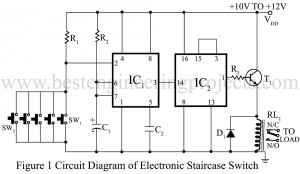

Read MoreStaircase Switch Circuit

If you want to control an electrical appliance from two places then you use the 2-way switch. But to control it from more than two locations (like operating a hotel’s staircase light from individual floors from various locations), the circuit “Staircase Switch” comes to your help. Due to the small size of the staircase switch circuit, it can be installed within a junction box. Circuit Description of Staircase Switch Circuit Staircase Switch Circuit utilize IC1 (NE555) as a timer with timing of 0.7 seconds, for this it is configured in…

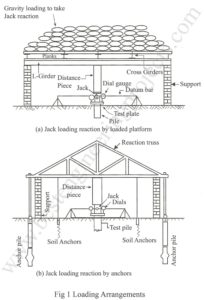

Read MorePile Load Test | Purpose of Pile Load Test

The purpose of pile load test is: To determine settlement under working load To determine ultimate bearing capacity To ascertain as a proof of acceptability Types of pile Load Test | Pile Load Test | Purpose of Pile Load Test In general two types of pile load tests are conducted. They are: Initial Test Routine Test The initial test is performed before the start of construction to assess the design adequacy. The routine test is performed on a working pile. This test is also known as work test. In initial test, the test…

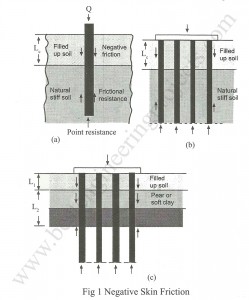

Read MoreNegative Skin Fraction on Single Pile and on Pile Group

Negative skin friction on pile occurs when the surrounding soil settles relatively more than the pile, causing drag force that increases the load on the pile and resulting in the reduction of carrying capacity of the pile. Such settlement may be due to the weight of the superimposed as shown in Fig.1, to ground water lowering or as a result of disturbance of clay caused by pile driving. The additional load due to negative skin friction may be so large as to cause overstressing of the pile material or may…

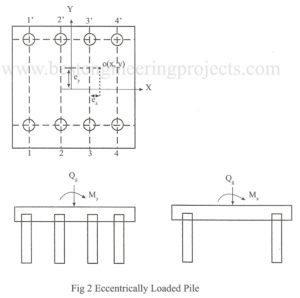

Read MorePile Groups Subjected to Eccentric Vertical Loads

When group of piles are loaded centrally over the pile cap, the load is equally distributed on all piles, provided the pile system is symmetrical and the pile cap is rigid and very thick and is in contact with the ground. Thus, when the total vertical load, centrally placed, is Qg, the number of piles is n, then the load transmitted to each pile shall be: When however, the pile cap is eccentrically loaded, as to subject the pile cap to a central vertical load Qg and additional bending moment…

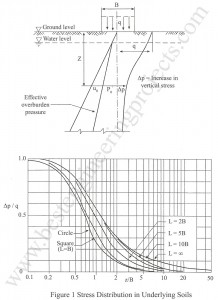

Read MoreDesign of Pile Foundation | Efficiency of Pile Groups

The spacing of the piles is usually predetermined by practical and economical considerations. The design of a pile foundation is usually comprises: Determination of the ultimate load bearing capacity of the group Qu(g) Determination of settlement of the group s(g) It is well known that the ultimate load of the group is generally different from the sum of the ultimate loads of individual piles Qu(s). ——— (1) Where, Ef = Group efficiency ratio Qu(g) = Ultimate bearing capacity of the pile group Qu(s) = Ultimate bearing capacity of single pile…

Read MoreBearing Capacity of Pile Groups in Clay, sands and in Gravel

Bearing Capacity of Pile Groups in Clay Experimental results have indicated that when a pile group installed in cohesive soil is loaded it may fail by one of the following ways. May fail as a block known as a block failure May fail individually in the group When piles are spaced at closer intervals, the soil contained between the pile move downward with the piles and at failure, pile and soil move together to give a typical “block failure”. Normally this type of failure occurs when spacing of the piles…

Read More