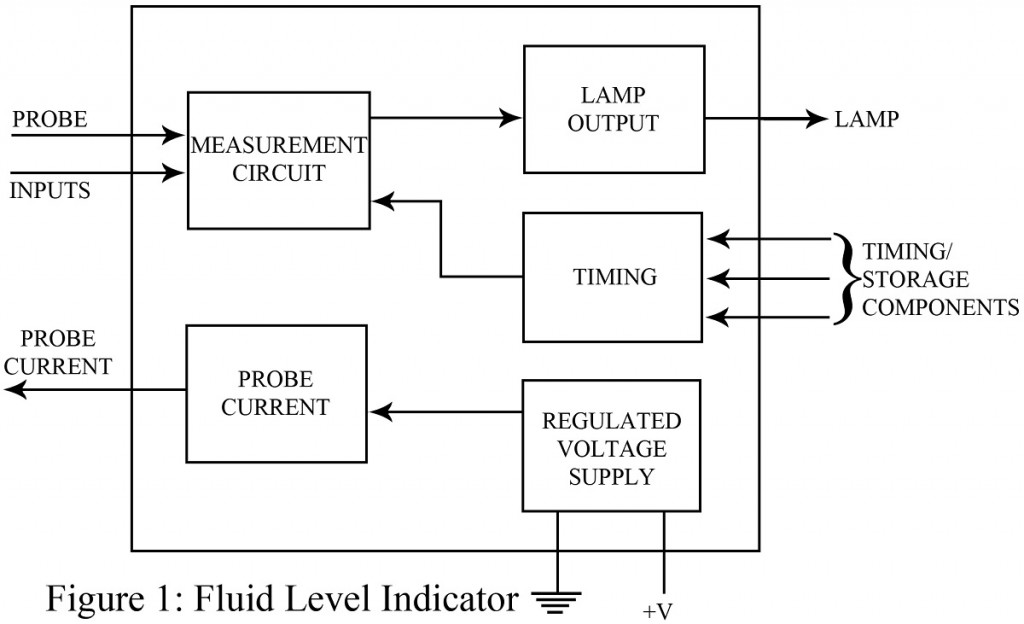

At times, determining the fluid level can become very tiresome. When the stored containers are dark-coloured, it gets more difficult. With automations taking over hectic activities, a special project, fluid level detector has been developed to eradicate this issue. The circuit of fluid level detector comes with a limitation; it can be used to measure non-flammable fluids only. In this particular circuit, the fluid level detector is used in conjunction with a thermo-resistive probe to measure the levels of fluids under consideration.

A light is interfaced to one of the output terminals the chip offers. The glowing light indicates the low level state of the fluids. In this section, we can design the light to flash briefly or remain in an ‘on’ state continuously. The circuit of fluid level detector comes with other benefits which include: transient protection, internal regulated supply, and short/open probe detection. In order to set reference values and supply a constant current for measuring, external passive components such as resistors, capacitors, and transistors are used, which are basic components in every electronic circuit. Here, a wire with high resistivity and temperature coefficient is used to develop a probe. Nickel and cobalt alloy can be the best solution available.

Basic key parameters are briefed below in points:

- Probe current reference voltage: – It is the voltage internally generated by the chip to regulate current to the probe. An external resistor is used to set the actual current value. Typical value is 2 V.

- Ramp thresholds: – These voltages are the threshold levels for the various tests and are in the tenths of volts range. They are measured by comparing the probe voltage (stored via an external capacitor) with internally generated voltages.

- Oscillator frequency: – The oscillator frequency is controlled by an external capacitor and this value is used to flash a warning indicator on and off. The approximated value is 2 Hz.

With this advanced circuitry, there are a lot of potential use cases. With its ability to accurately calculate the liquid levels or interfaces between liquids such as water, it is widely used in automation and also to make measurement simpler and efficient. It is not only used in industries to take very detailed measurements but due to it being cheap to produce, it is also used in a lot of small projects and by individuals in their personal projects.

Applications of Fluid Level Detector

This chip/circuit can be used to measure levels of automotive oil, hydraulic fluid, and coolant. It can also be employed in detecting Gas flow using the cooling of the probe by the flow of gas as an indicator.

Check out various Fluid/Water Level indicator/detector circuit posted in bestengineeringprojects.com

- Ultrasonic Water Level Meter

- Water Level Indicator Circuit using 7-Segment

- Water Level Indicator Circuit

- Water Level Controller Using NE555

There are countless ways in which liquid depth detectors can be used. Its use can be not only considered in industries but also in day to day uses, in every household. In a country where the major sources of water in the urbans are wells and personal small water storages, a water level detector may seem like one of the most obvious systems that can help to improve the quality of life in any house.

On homes depending on wells as a water source, being able to detect the quantity of water inside the well can be reassuring and on systems where the water is pumped onto a container to store it, it would be an easy and economical automation so constantly filling the containers would never be an issue. The number of such small inexpensive systems to be implement in a household in Nepal is countless and has a good prospect.