What are the types of sampler?

Usually there are two common types of sampler; thin walled Shelby Tubes or Piston Samplers. Besides these, there are some other types of samplers and they are: open drive samplers and split spoon samplers. These samplers are shown in Fig.1.

Shelby Tube | Types of sampler

The thin walled seamless steel tubes are called Shelby tubes. They are generally used to take undisturbed samples for routine site investigation works. The clear sketch of Shelby tube is shown in Fig.2.6 (a). The tube is pushed/driven into the soil. However, the tube should not be driven beyond 90 per Cent of its total length. After driving the Shelby tube, sampler is turned to shear the soil at base of the hole.

After taking out the sampler from the hole, the head and shoe of the sampler is removed. The top and bottom of the sampler are carefully waxed, capped and labeled for identification. In case of sensitive clays, Shelby tubes are not considered suitable. Generally, the diameter of the sampler varies from 40 mm to 125 mm and thickness ranges from 1.25 to 3.15 mm. In addition to these dimensions, the inside clearance ratio of the sampler shall be between 0.5 to 3 %.

Piston Sampler

In particular situations, when soils are much sensitive to disturbance or soil consists of silts and silty sands, which have some cohesion piston sampler is preferred. This type of sampler ensures the availability of samples of first class quality.

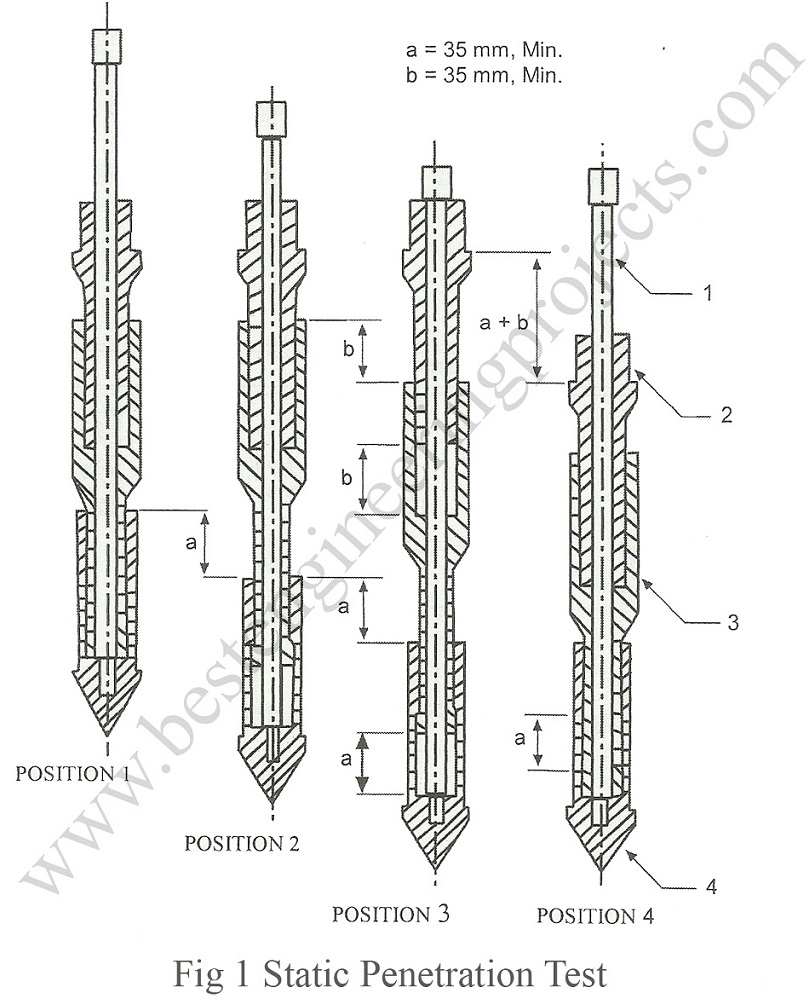

In market, several types of piston samplers are available. Among different type of piston samplers, the one designed by Osterberg has greater advantage to other samplers and is shown clearly in the fig.1 (d) . It consists of a thin-walled tube fitted with a piston. The piston is attached to length of rod, which passes through sampler head and run inside the hollow-boring rod. During the sampling process, the sampler is lowered into the borehole with a piston located at the lower end of the tube. The tube and piston are locked together by means of a clamping device at the top of the rods.

The piston acts as a sample protector since it prevents water or loose soils from entering the tube. The piston is fixed on the tube by clamping the piston rod to the casing and the thin walled tube is pushed past the piston into the soil to obtain the sample. The sampler is withdrawn with piston at the top of the sample held by a locking device in the sampler head. The vacuum between the piston and sample helps to retain the soil in the tube. Thus, the piston serves as a non-return valve since it collects soil samples and doesn’t allow back flow of soil. The piston sampler is pushed into the soil and should not be driven. Generally, the diameter of the sampler ranges from 40 mm to 100 mm but it can be large as 250mm.

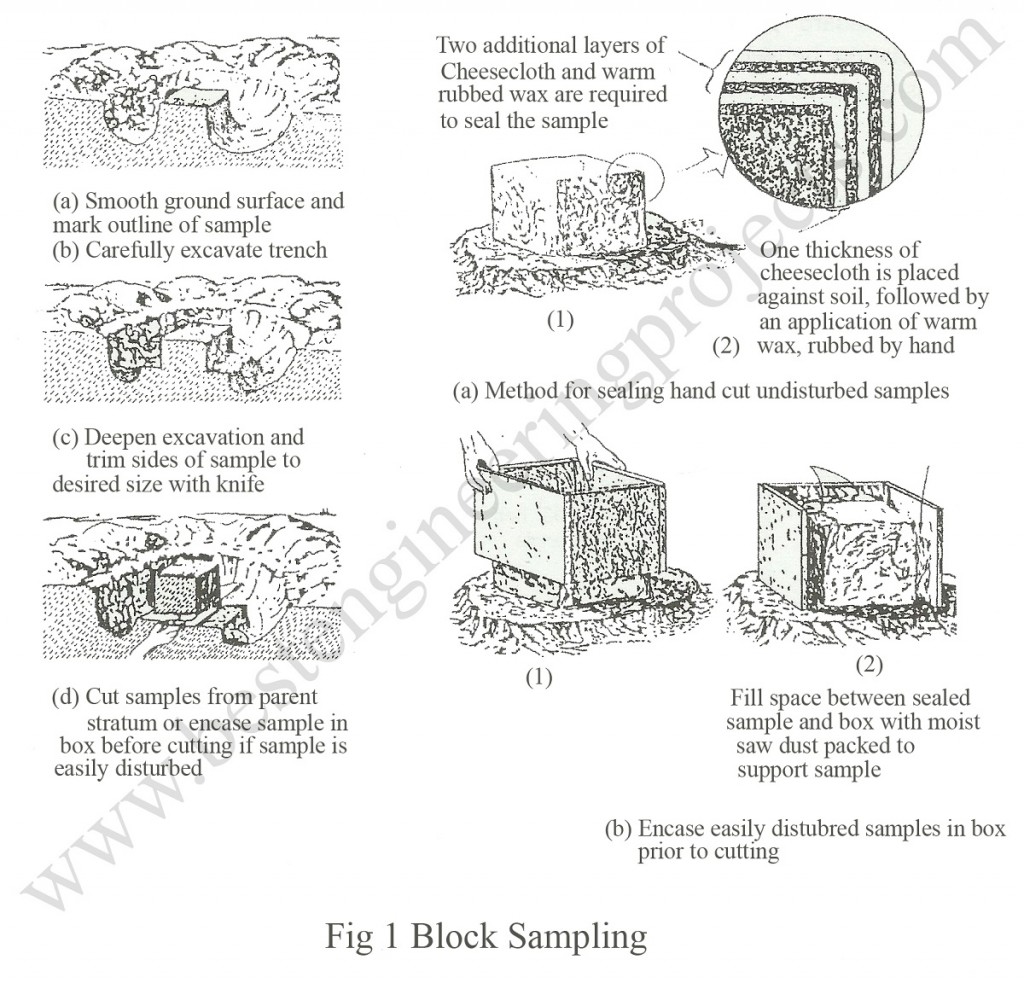

Block Sampling

For undisturbed samples, test pits and trenches can be considered the most reliable sources and they allow inspection of the soil in the place at shallow depth. Undisturbed block samplers can be hand carved from these excavations or obtained by penetrating samplers. This method is often more expensive than other undisturbed sampling method, but the greater value of the information obtained can compensate the high cost. In addition to undisturbed samples, information on the soil stratification and discontinuities can be obtained by this method and therefore has greater advantage. The fig 1 in below is self explanatory for block sampling.