When piles are driven in cohesive soil, the shear strength is changed radically due to occurrence of following phenomena.

- Remolding

- Ground heave

- Formation of an enlarged hole

- Strain softening

Remolding – Pile driving disturbs soil fabrics. This depends on sensitivity soils. With passage of time, the shear strength is regained due to the property called thixotropy. Soft sensitive soils regain their strength fully. After thirty days of driving about 75 % of strength is regained.

Ground Heave – When a pile is driven in clay pore water pressure is developed substantially around the perimeter of the pile. This phenomenon is most prominent into stiff to hard clay soils. The pore water pressure causes the soil to heave and cracks develop along radial direction. However, with passage of time the heave subsides and the soil consolidates.

Formation of Enlarged Hole – In the upper part of the pile, the vibration induced by driving forms an enlarged hole in stiff to very stiff clay. Radial cracks develop and a gap is formed between the pile and the soil. Pore water pressure is collected in the gap and the water lubricates the soil. As a result shear strength of the soil is reduced.

Strain Softening – When a pile is driven into a clay soil, large strain is developed. Due to this clay particles are reoriented. The shear strength is reduced drastically. The reduction can be of the order of 50 % of the peak strength at low strain. The strain softening effect is pronounced in normally consolidated clay.

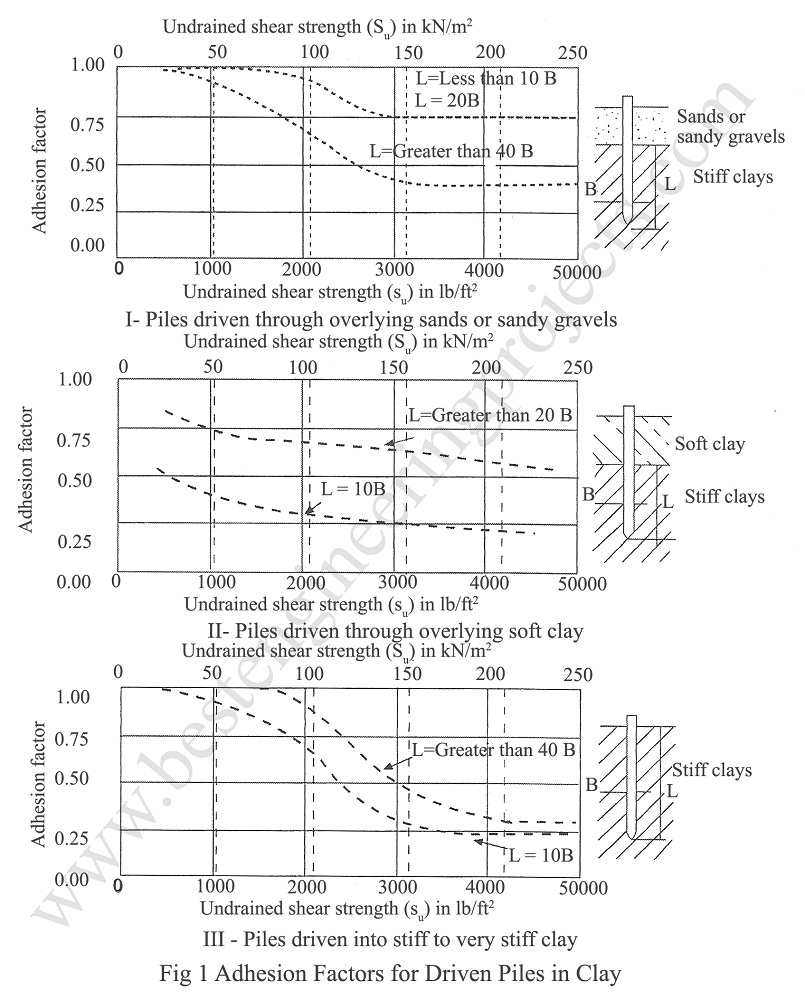

The adhesion factor is also influenced by the presence of other soils overlying the clay. Overlying soft clay results is smaller adhesion factors, while overlying granular soils give greater factors. The effect of other soils in the adhesion factors is described below.

Sands and Gravel Overlying Stiff clay – Driving piles into sands and gravels overlying stiff clay carries these soils along the pile shaft to a limited depth as shown in Fig.1.I. The skin of these soils has a high friction values such that the pile driven to penetrations of less than 20 diameters into stiff cohesive soils can have an ultimate skin frictional resistance exceeding 1.25 times the undrained shear strength of soils. For greater penetration, the effect of the skin of the granular material becomes progressively less and adhesion factor tends to decrease with increasing shear strength of soil. When the pile is driven to penetration of greater than 20 diameters, the adhesion factor is unity for shear strength of 75 kN/m2 and 0.75 for shear strength of 150 kN/rn2.

When the pile is driven to penetration of greater than 40 diameters, the adhesion factor is unity for shear strength of 25 kN/m2 and 0.4 for shear strength of 150 kN/m2.

Piles Driven into Stiff Clay through Overlying Soft Clay – When piles are driven through soft clay or silts into stiff to very stiff cohesive soils, a soft skin is carried down, again to a limited depth. The skin has a considerable weakening effect on the frictional resistance on the shaft when the pile penetrates the stiff cohesive soil by less than 20 diameters. When the ratio of length/width of the pile is less than 20, the value of should be taken as 0.4. When it is greater than 20 and undrained shear strength between 70 to 140 the value of

should be taken as 0.7 refer Fig.1.

Piles Driven into Stiff to Very Stiff Clay – When piles are driven through stiff to very stiff cohesive soils cause a gap to form around the upper part of the shaft such that skin friction cannot be assumed to act over this part. The gap is of considerable significance where piles are driven to penetration of less than 20 diameters. When the ratio of length/width of the pile is less than 20 and greater than 8, the value of should be taken as 0.4. When it is greater than 20 and shear strength between 70 to 140 kN/m2, the value of

should be taken as 0.7. For piles driven deeper than 20 diameters, the adhesion factor is governed by shear strength of the soil. The value of

decrease from unity for undrained shear strength up to 90kN/m2 to 0.4 at strength of 170 kN/m2 refer Fig.1.

Steel H – piles – For the ease of steel H-piles, the adhesion is usually calculated on a perimeter equal to twice the flange width plus twice the web depth, and end bearing on the gross cross-sectional area, that is, the flange width times the web depth.

Factor of Safety – In piles the allowable load is governed by settlement criteria. The working load for all types of piles in all types of soil may be taken as equal to sum of base resistance and shaft friction divided by a suitable factor of safely, which is normally taken as 2.5.

———- (1)

Where Qb is the base resistance and Qs is the shaft resistance. When Qb and Qs are measured separately the allowable load can be taken as:

———- (2)

It is permissible to take factor of safety of 1.5 for shaft resistance because the peak value of skin friction occurs at settlement of between 3 mm to 8 mm; where as the base resistance requires a greater settlement for full mobilization. The design load is taken as the least of the two values obtained by the above Eqs.(1) and (2).