In the article “Types of Waveguides” we will discuss circular waveguides, rigid waveguides, and Flexible waveguides.

Types of Waveguides

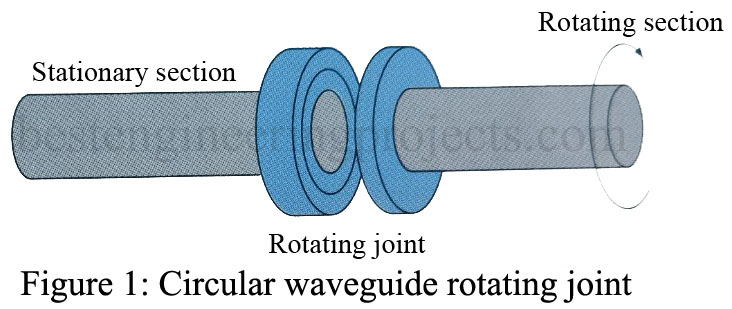

Circular Types of Waveguides: The dominant mode (TE10) for rectangular waveguides is by far the most widely used. The use of other modes or other shapes is extremely limited. However, the use of a circular waveguide is found in radar applications where it is necessary to have a continuously rotating section such as in Figure 1. Modes in the circular waveguides can be rotationally symmetrical, which means that a radar antenna can physically rotate with no electrical disturbance.

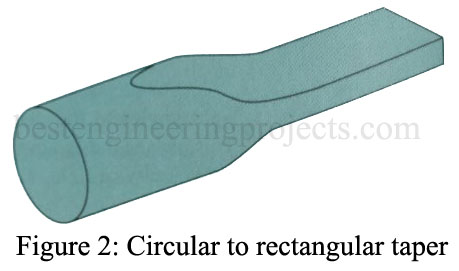

While a circular waveguide is simpler to manufacture than a rectangular one, for a given frequency of operation, its cross-sectional area must be more than double that of a rectangular guide. It is, therefore, more expensive and takes up more space than a rectangular guide. Typical radar systems, therefore, consist of the main run with a rectangular waveguide and a circular rotating joint. The transition between rectangular and circular waveguides is accomplished with the circular-to-rectangular taper shown in Figure 2. The transition is accomplished as gradually as possible to minimize reflections.

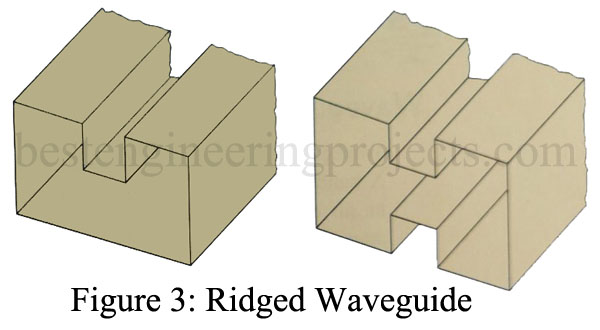

Ridged Type: Two types of ridged waveguides are shown in Figure 3. While it is more expensive to manufacture than a standard rectangular waveguide, it does provide one unique advantage. It allows operation at lower frequencies for a given set of outside dimensions, which means that smaller overall external dimensions are made possible. This property is advantageous in applications where space is at a premium, such as space probes and the like. A ridged waveguide has greater attenuation, and this, combined with its higher cost, limits it to special applications.

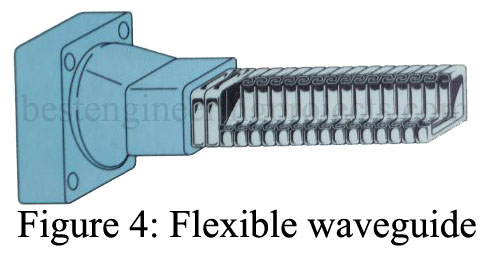

Flexible Type: It is sometimes desirable to have a section of waveguide that is flexible, as shown in Figure 4. This configuration is often useful in the laboratory or in applications where continuous flexing occurs. Flexible waveguides consist of spiral-wound ribbons of brass or copper. The outside section is covered with a soft dielectric such as rubber to maintain air and watertight conditions. These conditions are desirable so that corrosion of the waveguide’s inner surface does not occur.

Corrosion would cause an increase in attenuation through surface current losses and increased reflections. In critical applications, waveguides are filled with inert gas, and/or their inside walls are coated with noncorrosive (but expensive) metals such as gold or silver.