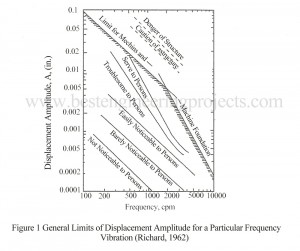

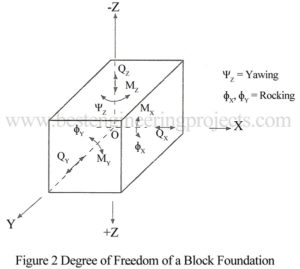

In this article we are discuss about “Design Criteria of Machine Foundation”. In the design a rigid block is assumed to rest directly in the soil. When acted by dynamic loads the rigid block as shown in Fig. 2 may vibrate in any one of six degrees of freedom and the complete evaluation of the response of the block is very complex. However many researchers have conformed from various studies that freedom of vibration in order to arrive at reasonable solution. A vibrating foundation fails when velocity or acceleration or…

Read MoreCategory: Civil Projects

Degree of freedom | Loads on Machine Foundation

What is degree of freedom? The Degree of freedom is defined as the number of independent coordinates which describe the motion of a system. Figure 1 (a) shows a system with one degree of freedom while, Fig.1 (b) shows a system with two degree of freedom. A foundation block as shown in Fig.2 has six degree of freedom. The block can undergo into six independent displacements. We can have translation in X, Y, and Z directions and also rotation in X, Y and Z directions. Loads on Machine Foundation The…

Read MoreMachine Foundation | Introduction and Description

Introduction to machine foundation: Foundations are subjected to static loads or dynamic loads or a combination of both static and dynamic loads. In addition to static loads, in some cases underlying soils are subjected to dynamic loads. Static loads produce no vibration and loads are imposed slowly. Dynamic loads produce vibration to foundation soil system. Various sources produce dynamic loads to soils supporting foundations. They could be from vibratory motion of machines, vehicular movement, earthquakes, bomb blasts, impact of hammers, mine explosions, pile driving, winds, waves and so on. Foundations…

Read MoreSoil Stabilization | Soil Stabilization Method

The process of improving the engineering properties of soils is called soil stabilization. It is the simplest method of soil stabilization. By soil stabilization, the soil becomes more stable by the reduction in the permeability and compressibility and by the increase in shear strength. With the increase in soil stabilization properties the bearing capacity of soil is increased significantly. The various method of soil stabilization includes: Mechanical Stabilization Cement Stabilization Lime Stabilization Bitumen Stabilization Stabilization by Geo-textiles Mechanical Stabilization | Soil Stabilization | Soil Stabilization Method In this method changing the…

Read MoreUnderpinning | Underpinning Methods and Purpose

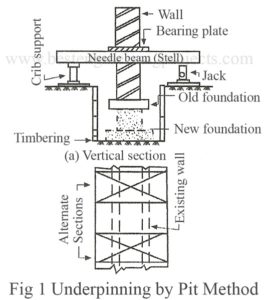

What is underpinning? Underpinning is a process of placing a new foundation under an existing one or strengthening an existing foundation. What are the Purpose of Underpinning? The underpinning is done to serve the following purposes. To strengthen a shallow foundation when a building with deep foundation is to be constructed adjoining it. To strengthen an existing foundation, which has suffered from cracks and settlements To deepen an existing foundation. To construct a basement under an existing building. What the Underpinning Methods? There are two underpinning Methods. They are: Pit…

Read MoreDrainage by Electro – Osmotic Method

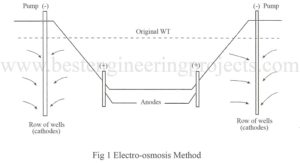

Electro-osmotic method is used when co-efficient of permeability lies between 10-7 cm/see to 10-5 cm/sec. In electro-osmotic method, two electrodes are driven into the saturated cohesive soil. The cathode is made out of steel in the form of a well point or a tube. A steel rod or a pipe or a sheet piling is made to serve as anode as shown in Fig.1. In general the surface of soil is negative charged and is surrounded by polar water and ions of other elements. When a current is passed through…

Read MoreDrainage by Vacuum Method

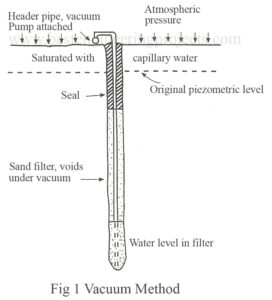

If the effective size of the soil to be drained is less than 0.05 mm, well points cannot be used because capillary forces prevent flow. In order to drain such soils suction head in excess of capillary head is to be applied i.e. by vacuum method. The typical soils of such nature are sands and silty sands. These soils possesses, coefficient of permeability between 1 ×10-3 to 1 ×10-5 cm/sec. Drainage in such cases can be made efficient by the use of vacuum well points as in Fig.1. Vacuum well…

Read MoreDeep Well Pump

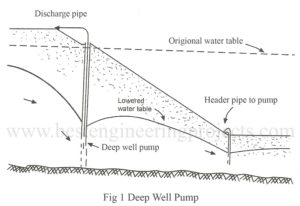

For very deep excavation the multistage well point set up has the disadvantage that the water level is pulled down abruptly at the edge of the excavation. As a consequence, the hydraulic gradient near the excavation bottom becomes quite large and the resulting seepage pressures may lead to the instability of the side slopes. Under such circumstances a deep well pump is suitable as shown in Fig.1. Deep wells pump are cased holes and generally they have diameters ranging from 30 cm to 60 Cm. The depth of deep well…

Read MoreWell Point System | Types of Well Point

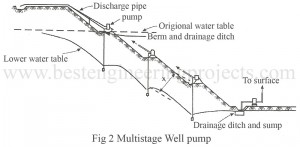

What are the types of well point System? There are two types of well point system, namely single stage well point system and multi-stage well point system. These systems are briefly described in the following. Single Stage Well Point system – A well point consists of a pipe about 1 m long and 50 mm in diameter. It has perforations, which are covered with a screen to prevent clogging in. At the lower end, a jetting nozzle is provided. This nozzle also acts as a driving point. A ball valve…

Read MoreDrainage | Drainage from Open Sumps

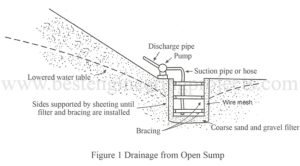

What is drainage and where it is required? Drainage is required whenever it is desirable to eliminate seepage pressure or to reduce danger from frost damage or to increase shearing resistance of soil by reducing neutral stresses. These objectives are achieved by lowering the water table below the level of a mass of soil requiring protection. When the co-efficient of permeability exceeds 0.001 cm/sec drainage is essential. When value of coefficient of permeability lies between 0.001 to 0.00001 cm/sec drainage is inconsequential but it is required for stability of sides…

Read More