What is Caissons?

The term caisson is derived from Latin, which means box or case. Caissons are hollow inside and usually constructed at site and sunk in place into a hard bearing stratum. Often the caissons have high construction cost and their construction is restricted to major foundation works.

Caissons are used for bridge piers, abutments in rivers and lakes, docks and wharves, break water and other shore protections works, and large water front structures such as pump houses subjected to very heavy vertical and horizontal loads.

Advantages of Caissons – The construction of caisson is advantageous to other deep foundations when the soil contains large boulders which obstruct penetration of piers and drilled piers, when a massive substructure is required for protection against floating objects and sand scour or when foundations subjected to lateral forces such as waves. For conditions other than these, caissons are generally more expensive than other deep foundations.

Types of Caissons

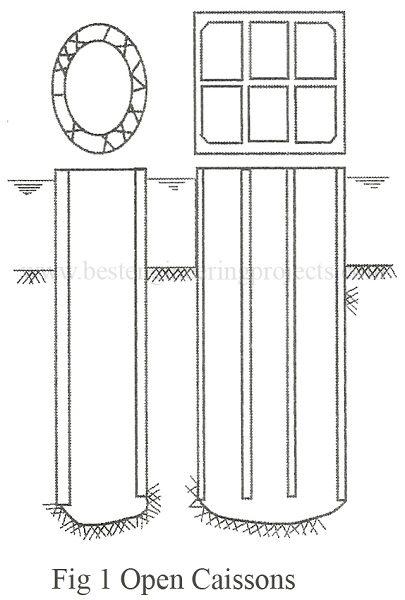

Depending upon the method of construction caissons are classified into three categories. They are shown in Fig. 10.4.

(a) Open Caissons (Well foundation)

In open caissons or well foundations the top and bottom are kept open during construction. The caisson is sunk in place as grab buckets through water remove soil. Upon reaching its final position a concrete seal, usually 1.5 m to more than 4.5 m thick, is deposited through water. The schematic diagram for open caissons is shown in Fig.1.

Advantages of Open Caissons- The advantages of open caissons are their feasibility to be sunk to great depths. Their construction cost is relatively low.

Disadvantages of Open Caissons- The disadvantages of the open caissons are that the bottom of the caisson cannot be thoroughly cleaned and inspected. The concrete seal placed in water is not satisfactory and soil near the cutting edge may require hand excavation by diver. If obstruction like boulders or logs are encountered the construction gets slowed down.

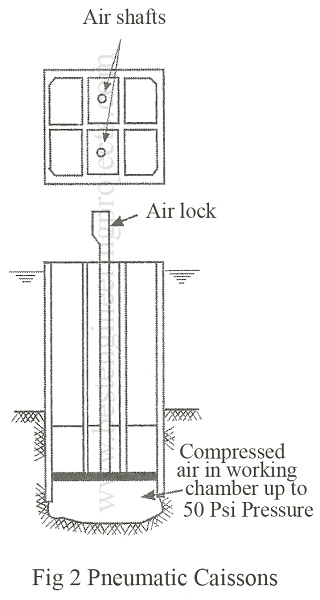

(b) Pneumatic Caissons

The top of pneumatic caisson is closed and contains a working chamber as shown in Fig.2 at which pressure greater than atmosphere is maintained. The compressed air used to exclude water from entering the working chamber enables the excavation. Concreting is to be done in the dry condition.

Advantages of Pneumatic Caissons- The advantages of pneumatic caissons are that all work can be done in dry and there is control over work. The foundation is prepared better and plumbness of caissons is easier to control. The concrete placed in dry condition will have good and reliable quality. The obstruction from boulders and logs can readily be removed and excavation by blasting may be done if necessary.

Disadvantages of Pneumatic Caissons- Pneumatic caissons have high cost of construction. They cannot be sunk to depths greater than 35 m because the higher pressure below this depth cannot be resisted by human body.

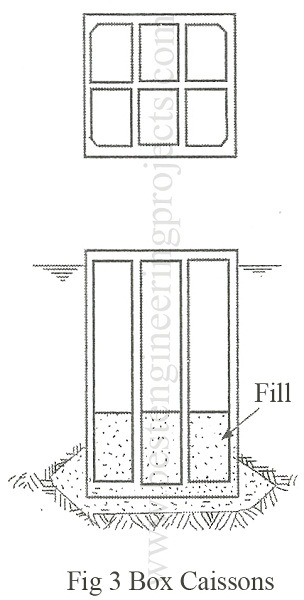

Box Caissons

The box caissons are closed at the bottom and open at the top as shown in Fig.3. They are usually fabricated on land, floated to site and sunk in position. While sinking sand, gravel, concrete or water are filled inside the caisson. This type of caisson is suitable when hard strata are available at shallow depth. Sometimes false bottom made out of wooden planks are also used for floating.

Advantages of Box Caisson- The advantages of this caisson is its cost of construction. It is used when construction of caissons at site not feasible or costly.

Disadvantages of Box Caisson- The disadvantages of this type of caisson are that the bearing strata should be level or made level. This type is feasible only when suitable bearing stratum is available at shallow depth. Provision should be made for scour protection. The bearing stratum is often not compact.