Bearing Capacity of Pile Groups in Clay

Experimental results have indicated that when a pile group installed in cohesive soil is loaded it may fail by one of the following ways.

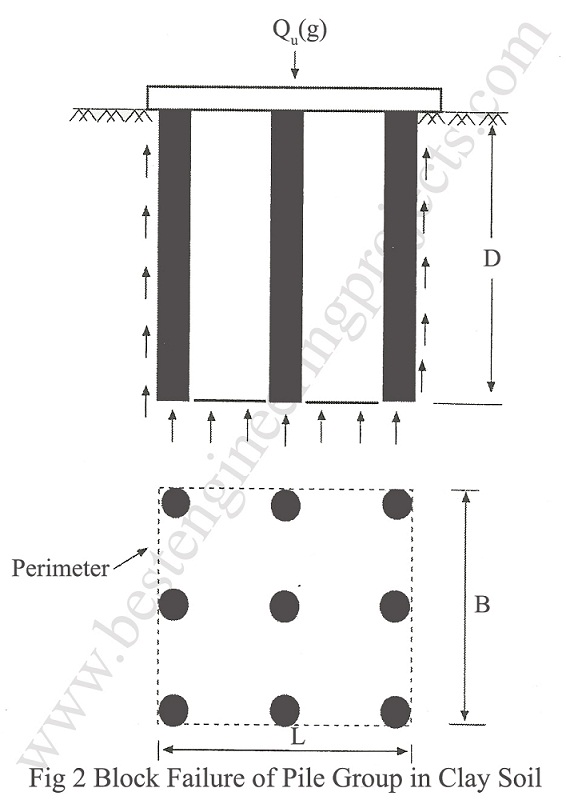

- May fail as a block known as a block failure

- May fail individually in the group

When piles are spaced at closer intervals, the soil contained between the pile move downward with the piles and at failure, pile and soil move together to give a typical “block failure”. Normally this type of failure occurs when spacing of the piles is in between two to three times the pile diameter. For wide spacing, pile in the group fail individually. The efficiency, which is defined as ratio of average load per pile in the group at failure to the load at failure of a single comparable pile, is less than unity at closer spacing and may reach to unity at a spacing of about 8 times the pile diameter.

Individual Failure

———- (1)

Where, ———- (2)

———- (3)

Block failure

———- (4)

Where, (base area of pile group)

(perimeter area of pile group)

Nc = Skempton’s bearing capacity factor (Taken as 9)

D = Depth of block

su = Undrained shear strength at the base

su‘ = Average along the pile length

Again. ———- (5)

The pile capacity is taken as the least of the values given by Equations 3 and 5.

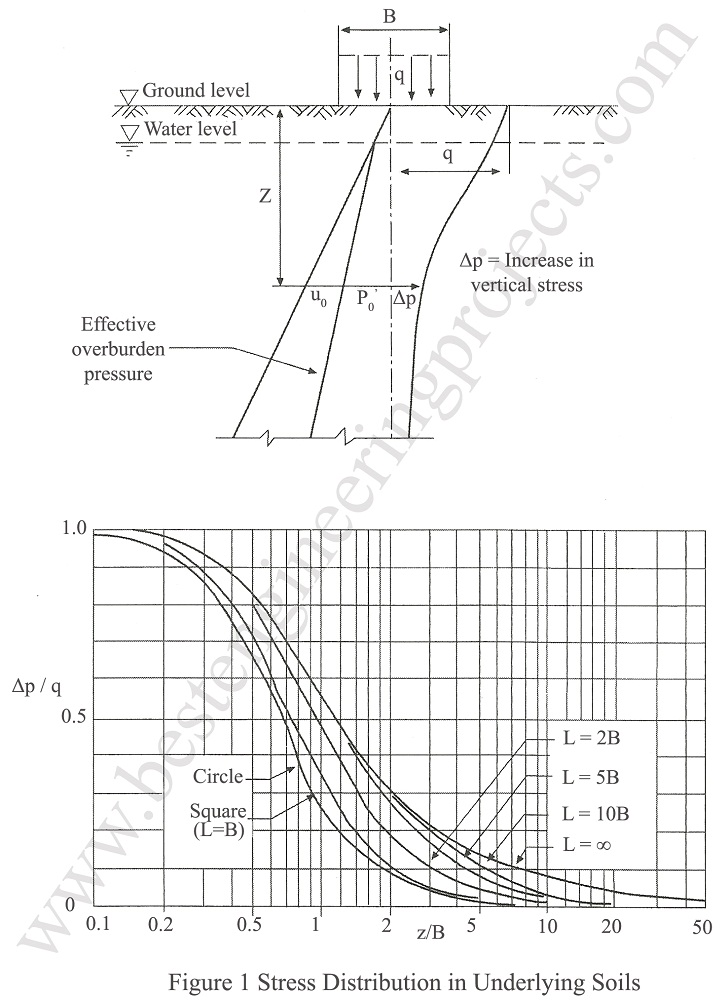

Bearing Capacity of Pile Groups in Sands and Gravels

When piles are driven into loose sands and gravels, the soil around the piles to a radius of at least three times the pile diameter are compacted. The sand gets highly compacted if driven at closer spacing. Model test on pile groups has shown that a maximum efficiency of 2 for piles driven in sands and gravels. However, more recently Vesic, by means of large model tests have shown lower efficiency ratios. Bearing in mind the effect of soil compressibility, it is not advisable to count in design, the efficiency ratio greater than unity. The recommended efficiency for piles driven in sands and gravels is unity. Hence, we can write:

———- (6)